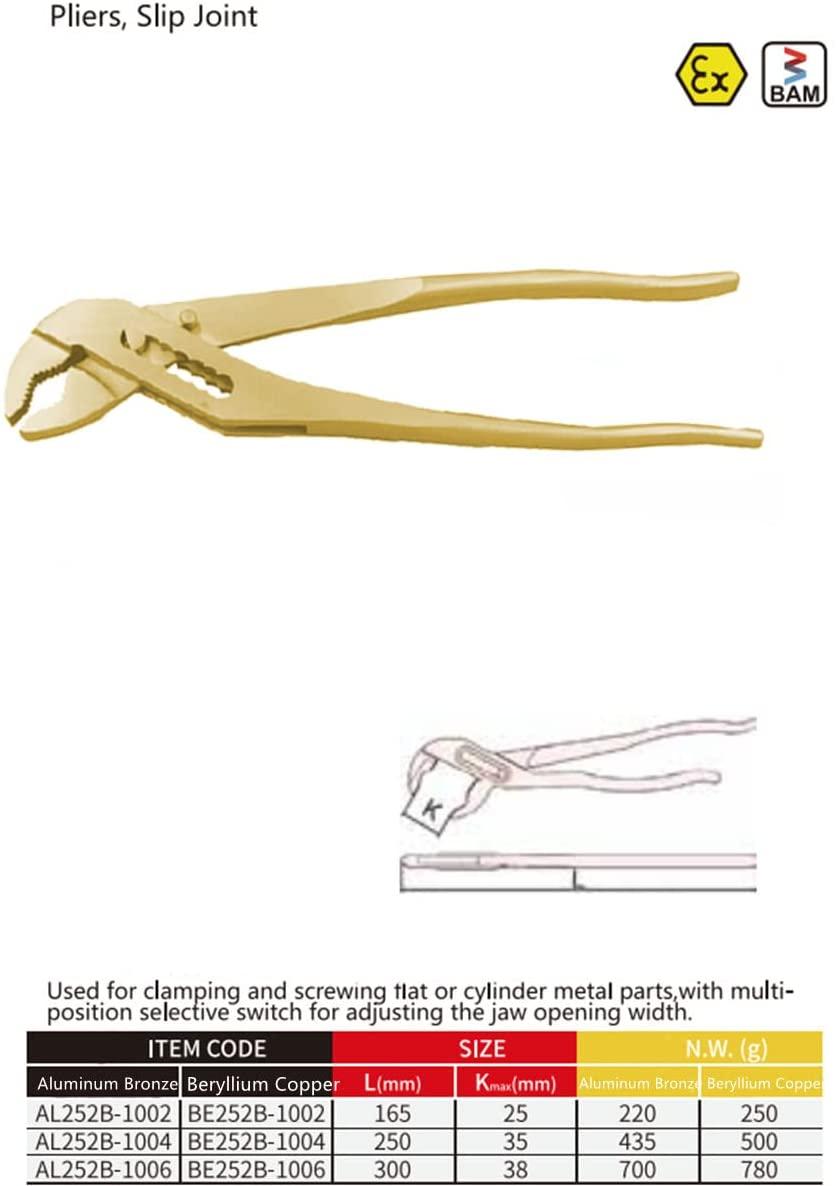

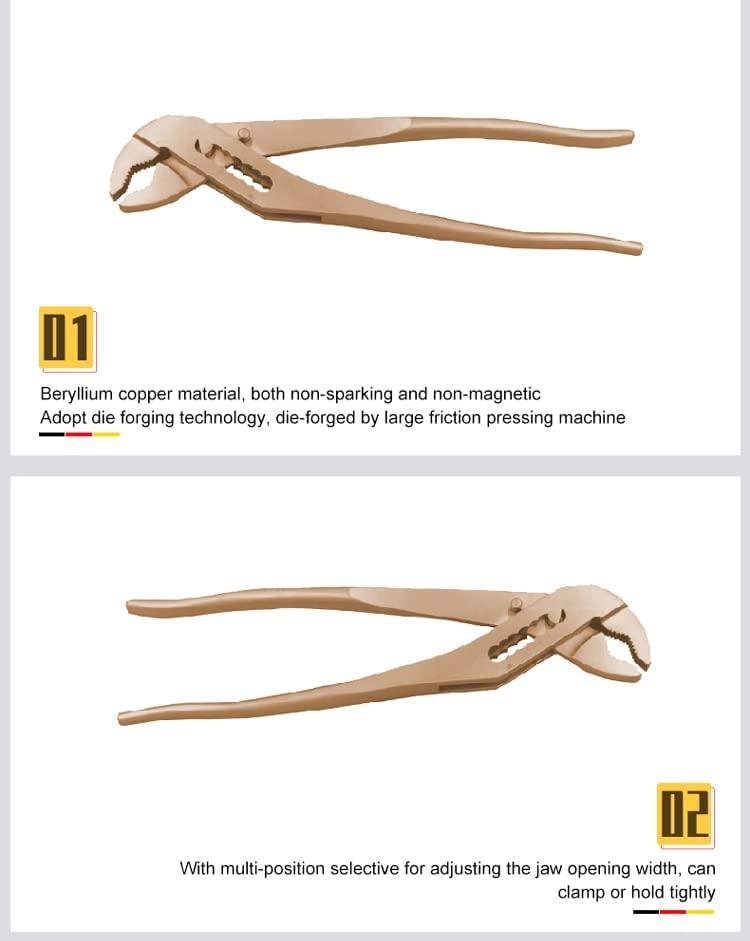

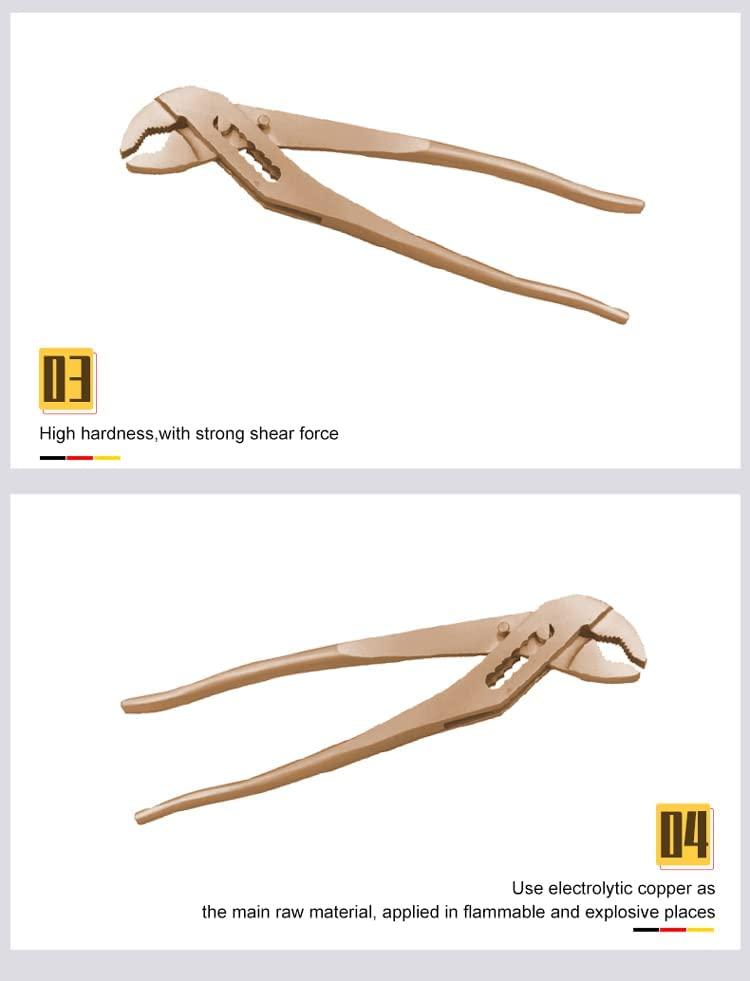

WEDO Non-Sparking Slip Joint Pliers, Spark-free Safety Slip Joint Pliers, Beryllium Copper, Non-Magnetic, DIN Standard, BAM & FM Certificate, 12Inch, 300mm

$84.95

-

Returns & Exchanges within 30 daysAny return for unsatisfied item(s) is available in 30 days

-

Worry-Free ReturnsSeller covers return shipping

-

Money Back GuaranteeA full refund within one week upon receiving your return

-

3-Month WarrantyCovering any possible defect in materials and workmanship